Getting The Outsourced Warehousing And Fulfillment To Work

Table of Contents10 Easy Facts About Outsourced Warehousing And Fulfillment ExplainedThe Buzz on Outsourced Warehousing And FulfillmentThe 15-Second Trick For Outsourced Warehousing And Fulfillment7 Simple Techniques For Outsourced Warehousing And FulfillmentThe 2-Minute Rule for Outsourced Warehousing And FulfillmentThe 5-Minute Rule for Outsourced Warehousing And Fulfillment

As even more companies outsource their warehousing, they'll need to see to it they're picking the right partner to guarantee the greatest degree of solution. It's easier to take the next action in your endeavor currently that you have a firm understanding of warehousing. Having the ability to identify the appropriate stockroom services and pertinent collaborations can spend some time; do not rush on your own.Warehousing is the procedure of keeping and also delivering physical products in a storehouse. Warehouses can be utilized in various organization settings for saving goods before shipping them to a details place or different customers. An organization like Walmart might use a warehouse to keep its goods in mass and also ship them to its stores when inventory falls short, as well as things are needed to be placed on shelves.

You may have seen terms storage facility and also warehouse are made use of mutually. Well, practically they are various. A warehouse is just a building that is used to save supply. Whereas a circulation center not just shops the inventory, however additionally offers an order gratification facility through the procedures of picking, packaging, as well as shipping.

Fascination About Outsourced Warehousing And Fulfillment

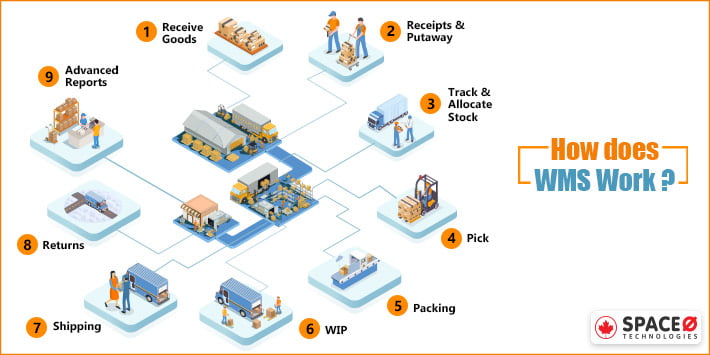

A product that comes and also goes in as well as out of a warehouse goes with numerous processes. The inbound procedure is receiving and also saving products from a provider to a storehouse or a gratification.

These are as follows: After the trailer is docked at the storehouse, workers examine the inventory to make certain that all items that were anticipated exist and also are not damaged. The stock is appointed Certificate Plate Numbers (LPNs) as well as taken for putaway. After the inventory is checked in the getting process, it is required to storage where it is kept.

Some storehouses store items with each other based upon the thing type or called for storage temperature etc. to maximize storage locations to maximize place use. The outgoing Refine is the selecting, packing, and shipping of items from the stockroom to a client or end customer. The outgoing process is additional separated right into the adhering to processes - outsourced warehousing and fulfillment.

Outsourced Warehousing And Fulfillment Things To Know Before You Buy

Picking is the process of accumulating all the items in order from their particular storage space areas and transferring them to a staging area. When all things in an order are picked and given a hosting area, the next step is to get them prepared to be shipped to the client or end individual.

The last step in finishing an order after it has been selected and packed is to pick a suitable service provider, load the order on the provider and also ship it to the customer's delivery address. All the above actions as well as procedures involved with warehousing can conveniently be managed as well as kept track of using a Stockroom Management System.

A storehouse management system (WMS) includes software application and also procedures that allow organizations to manage and also administer storage facility procedures from the moment goods or materials get in a warehouse till they vacate. Storehouses rest at the facility of production and also supply chain operations because they hold all of the material used or created in those processes, from resources to complete products. outsourced warehousing and fulfillment.

Not known Details About Outsourced Warehousing And Fulfillment

For instance, if raw products are not gotten appropriately or parts are misplaced in a storage facility, the supply chain may be right here reduced or interfered with. WMSes are critical in ensuring that these procedures work efficiently by tracking stock and seeing to it that products are stored as well as sorted effectively, in addition to shipped as well as tracked accurately.

The WMS handles the information and procedures relating to the motion of items through a storehouse. Number 1 shows each system's duty in processing orders and also the types of information they require to share with each other to guarantee that the appropriate product gets to the client on time.

Its function in inventory is to track the stock data that can be found in from barcode visitors and radio regularity recognition (RFID) tags as well as update the inventory monitoring module in the ERP system to guarantee it has the current info. A combination web link integrates the inventory data that is saved in the ERP system and the WMS.

The 5-Second Trick For Outsourced Warehousing And Fulfillment

It is essentially a database of thorough details regarding shipping service providers yet is likewise a transactional as well as interaction system for preparation, performing and tracking the deliveries. Occasionally a TMS will be integrated with the WMS to enable far better control of the inbound and also outbound logistics tasks that occur Visit Your URL at the interface of stockrooms and freight shippers, such as palletization of products, labor scheduling, yard management, load building as well as cross-docking.

, including area picking, wave picking and also set selecting. Stockroom workers can additionally use lot zoning and also task interleaving functions to assist the pick-and-pack tasks in one of the most efficient way., which allows the WMS to send out costs of lading (B/L) ahead of the shipment, create packaging listings as well as invoices for the shipment and also send out breakthrough delivery notices to recipients.

The major attribute of a cloud-based WMS versus the conventional on-premises system is that the software program is organized and also taken care of by the WMS Website vendor or a cloud company. This takes the burden of setting up, handling and also updating the system off the company's IT department. Due to the fact that they are easier to set up and also less pricey to manage, cloud-based WMSes often tend to be favored by SMBs.

Outsourced Warehousing And Fulfillment Things To Know Before You Buy

Pros of cloud-based WMS include the following: Faster implementation. Traditional on-premises WMSes can normally take months to execute, whereas cloud-based WMS implementations can be finished in weeks, relying on the intricacy. This suggests that organizations have a much faster path to a positive ROI and also can make use of the cloud WMS capacities faster, which is a huge advantage in the busy contemporary economic climate.